How Digital Printing can Save You Time, Stress, and Money.

How Digital Printing can Save You Time, Stress, and Money.

Blog Article

Digital Printing - The Facts

Table of ContentsThe Best Strategy To Use For Digital PrintingNot known Factual Statements About Digital Printing Digital Printing Fundamentals Explained

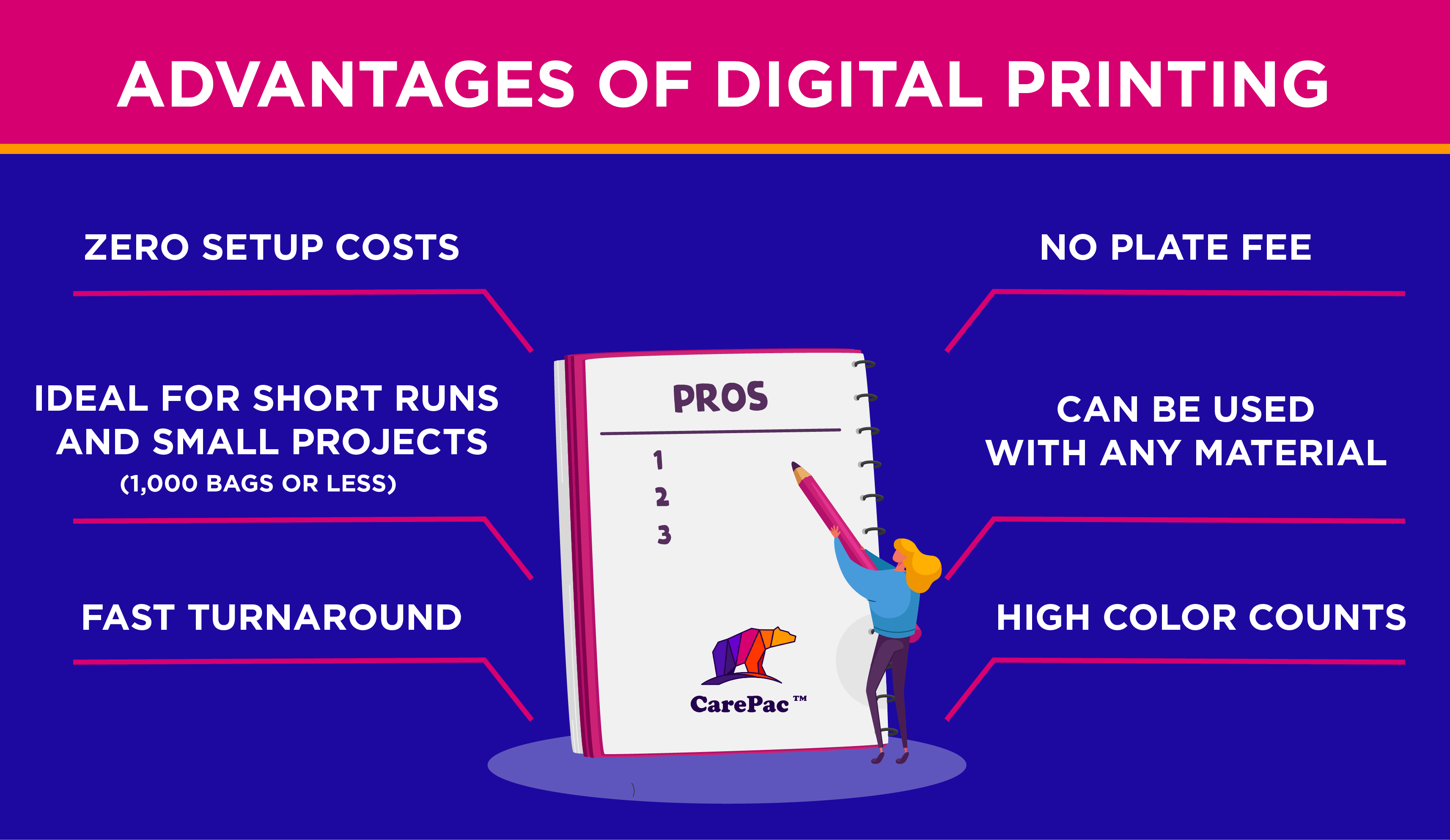

Digital printing likewise needs very little configuration. Right here are the essential ways in which electronic printing sustains greener practices: One of the substantial environmental benefits of electronic printing is minimizing waste (Digital Printing). Typical printing methods, like lithographic printing, often waste significant quantities of paper and ink throughout the configuration phase.

Digital printing presses remove the need for these plates, dramatically lowering configuration costs. Digital printing presses can incorporate variable data right into your prints, which enables extremely customized advertising and marketing products (Digital Printing). By personalizing your advertising products, you can boost engagement with possible consumers and improve the chances of converting them right into actual clients

Digital printing presses offer outstanding shade consistency and accuracy, leading to better prints. With electronic printing, you can be certain that the shade of your prints will certainly be constant from one print job to the following. A number of years ago, many consumers did not approve direct-injection digital printing due to the fact that the high cost. The acquisition expense of a set electronic printing tools goes to least 150%of the standard printing and coloring equipment, which boosts the.

Digital Printing Things To Know Before You Buy

In order to avoid deterioration of the nozzle, the ink for digital printing is a lot more expensive than the ink for typical printing, and additional ink filtration is needed during the printing procedure. In digital inkjet printing, the pattern is straight published on the material, getting rid of the plate making in rotating screen printing. Yes, are a lot more expensive than standard printing inks, but the digital printing procedure can conserve ink consumption.

Today, the electronic direct-injection printing press has gone from proofing to the phase of medium-sized and large-sized production. The electronic direct-injection machine has actually gone with the promotion period and went into the growth and maturation duration. Both printing residences and brand proprietors know the development potential of electronic printing, and agree to raise financial investment in electronic printing. The print quality can in some cases even competing that of offset printing. Digital printing is a lot more economical for short print runs since it needs much less pre-press activities and less configuration than offset printing. If an error in offset printing is not captured prior to the plates are made, it will be very costly to make new ones. While every person seriously hopes that mistakes will be stayed clear of, it is reasonable to prepare for their potential modification. Furthermore, its accuracy is very high. This ensures harmony in look across the board, reducing the possibility that any kind of piece will certainly require to be thrown away as a result of problems. Ensuring home plates are in location, the ink secret is calibrated, and all the necessary changes have been made is a taxing process when balanced out printing. Reduced pre-press actions suggest less time is needed to set up the press. This leads to a significant acceleration of turnaround time. When you require published products quickly, this is an excellent choice. Digital printing can be a lifesaver when you obtain an order in go now the nick of time.

Variable data printing, such as straight mail with customized codes and addresses, is ideally matched for electronic printing. Digital fast printing just requires four actions of layout, evaluation, printing and binding to obtain everything done. Digital fast printing has an unequaled advantage: print on demand.

Report this page